ActiveStent

Sustainable Functionalization of Stents to Prevent Urinary Tract Infections

Challenge

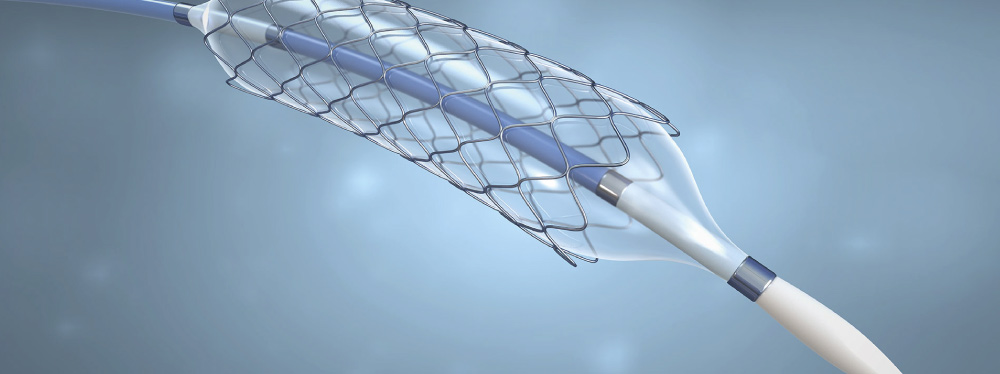

Ureteral stents are a simple and invasive method that ensures renal function, treats the pain caused by renal obstruction and avoids the use of external and visible devices. However, implantation of ureteral stents is associated with irritation on emptying, discomfort and lower back pain-hematuria, and urinary tract infections that may require (early) stent replacement, antibiotic administration and hospitalisation due to biofilm formation on the surface of these devices.

Although there are several options, no existing solution on the market is able to significantly reduce the symptoms caused by urethral stents. Thus, it is imperative to develop and implement new concepts capable of reducing the morbidity of stents.

Solution

The proposed solution is the application of a coating, through the sputtering technique, to functionalise the ureteral stent, modifying its surface with active compounds, such as antimicrobial agents. Among the antimicrobial agents, metallic nanoparticles, namely Ag and Au, are the best known due to their proven efficiency and team knowledge.

The objectives of ActiveStent are:

a) To prove the antimicrobial efficiency of the coatings by testing them with a wide variety of pathogens (bacteria and fungi), at different application times, evaluating their efficiency over time and whether they match the requirements imposed by urologists for their clinical application (short term and long term);

b) To evaluate the toxicity of the coatings used in stents in different cell lines of the constituent tissues of the urinary system and the biocompatibility of the coating deposited on the surface of the stent in an in vivo environment.

Objectives, Activities and Results expected / achieved

Activities and expected results:

i) To confirm the antibacterial action of the coatings produced, in the presence of other bacteria different from those previously tested, opening the possibility of the functionalised stents being subsequently certified according to ISO 22196;

ii) To evaluate the antifungal action of the thin films deposited on the stents;

iii) To certify the antimicrobial action time, testing the coated stents at longer time intervals than those previously studied;

iv) To study the toxicity of the coatings used in the stents in different cell lines of the constituent tissues of the urinary system;

v) To evaluate the in vivo biocompatibility of the coatings placed on the stents;

vi) To implement the coating process on an industrial scale, using a production equipment with adequate characteristics for the coating of parts with complex geometries, such as stents.

Achieved Results:

The ActiveStent project has achieved important results in the area of medical device coatings:

i) Production of carbon-based thin films on ureteral stents;

ii) Evaluation of the antimicrobial action, with mixed biofilms (bacteria and fungi), over time;

iii) The coatings showed viability for one of the tested cell types over time;

iv) Production of the coatings on an industrial scale.

Project Reference

CENTRO-01-0145-FEDER-181221Funding

Intervention Region

Center of Portugal (100%)Total Investment

149.661,77IPN Investment

68.114,63Total Eligible

149.661,77IPN Eligible

68.114,63EC Funding – Total

125.743,36EC Funding – IPN

57.897,44Duration

12 MonthsStart Date

2022-07-01End Date

2023-06-30Approval Date

2022-06-22Consortium

Universidade de CoimbraInstituto Pedro Nunes

TEANDM - Tecnologia, Engenharia e Materiais S.A.

Keywords

Sustainable functionalization;Coatings;

Ureteral stents;

Renal function.