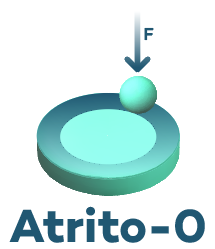

ATRITO-0

The synergy between texturization and self-lubricating coatings for more energy-efficient and environmentally friendly mechanical contacts

Challenge

The main challenge of this project is the significant reduction of friction in lubricated mechanical contacts through the synergistic effect of adaptive self-lubricating coatings based on transition metal dichalcogenides (TMDs), deposited on textured surfaces. With the proposed approach, we intend to achieve an overall decrease in friction in all kinematic regimes of lubrication (dry, boundary layer, mixed and hydrodynamic), even while eliminating the environmentally pernicious additives used in lubricants.

Solution

To achieve the project objectives, the work program will start with the industrial implementation of the deposition of TMD-based coatings (WSC and MoSeC). Surface texturing will be carried out in a two-step process by electrical discharge machining (EDM), using previously textured electrodes using laser or micromachining techniques. After lubricated tribological tests, the formation of TMD tribolayers on the contact surfaces will be studied, as well as the influence of test conditions on the coefficients of friction and wear. This type of approach will be replicated with the textured samples coated with TMD in order to investigate the role of topography in liquid / solid lubrication.

Complementarily, the research will be supported by theoretical modeling and simulation studies to optimize the distribution and size of topographic details and understand the formation of the TMD layer by self-adaptation. Regarding partners' involvement, IPN will demonstrate the suitability of using the two-step texturization process (electrode texturization + EDM) for the large-scale production of textured components, while Mahle will advise the consortium on the application of the results and participate in the industrial testing of a surface-modified prototype according to the optimized solution achieved.

Objectives, Activities and Results expected / achieved

Results achieved:

1. Steel textured surfaces with predefined geometries can be produced on demand using laser technology and EDM. Graphite electrodes have been produced using laser texturing and later used to textured steel surfaces by EDM;

2. WSC coatings with optimized properties have been deposited on samples using magnetron sputtering;

3. The properties of the coatings have been fully characterised regarding their molecular and elemental compositions, thickness, hardness, and Young modulus. Tested samples have been investigated using optical microscopy, 3D profilometry, SEM/EDS, and Raman spectroscopy;

4. The textured surfaces were submitted to tribological tests, namely block-on-ring, cylinder-on-flat, and flat-on-flat. Overall, textured coated samples produce better results than textured uncoated samples;

5. Wear tracks have been investigated using several characterisation techniques. Traces of iron oxides have been found in scarred textured regions;

6. A finite element method model based upon the Reynolds equation was developed. This model predicts the coefficient of friction (COF) and Stribeck curves for various textured and non-textured surfaces and for different lubrication regimes.

Project Reference

POCI-01-0145-FEDER-030446Funding

Intervention Region

North (32.24%) and Center (67.76%) of PortugalTotal Investment

237.183,92IPN Investment

36.100,00Total Eligible

237.183,92IPN Eligible

36.100,00EC Funding – Total

FEDER - 201.606,33EC Funding – IPN

FEDER - 30.685,00National public financial support – Total

OE - 35.577,59National public financial support – IPN

OE - 5.415,00Duration

48 MonthsStart Date

2018-06-01End Date

2022-05-31Approval Date

2018-02-27Consortium

Universidade de CoimbraUniversidade do Minho

Instituto Pedro Nunes

Mahle - Componentes de Motores, S.A.

Keywords

Ultra-low friction;PVD coatings;

Surface texturing;

Lubricated contact;

Ultra low friction;

PVD coatings;

Surface texturing;

Lubricated contact.