SMART ACTIVE MOULD (SAM)

Optimization of the Thermal Performance of Injection Moulding

Challenge

Injection molding is an industry-leading process capable to produce superior quality components, high complexity and freedom of design, where replication is fast and effective. Nonetheless, the temperature control system, despite being one of the most critical aspects of the process, is still designed empirically. As a consequence, many defects in molded parts are due to non-uniform cavity cooling with the physical properties and appearance of the molded part influenced by their rate of change.

Solution

The main objective of SAM - Smart Active Mould - was to strengthen research, technological development and innovation.

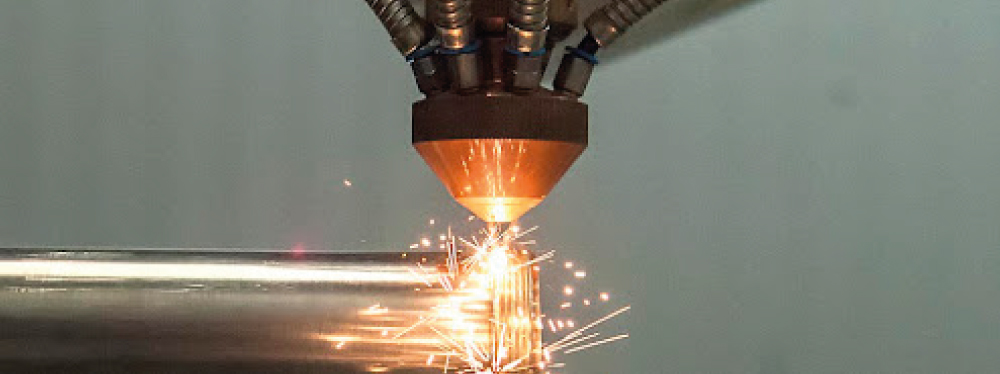

The SAM project aimed the investigation of an innovative mould-level solution to dynamically control the temperature of the injection moulding process of polymer parts. This new approach was supported in new technologies of thin coatings and additive manufacturing resulting in an increase of the quality of the moulding parts, leading to parts without defects or distortions, reduction in the time of manufacture, possibility of processing new materials and products with more complex shapes and specifications. The new solution was a technological leap, since it was pioneer in the integration of the different technologies into a single product directed to injection molding of high quality polymeric components for high end products.

Objectives, Activities and Results expected / achieved

The purpose of the SAM project was to tackle several points considered crucial in the injection moulding process with relevant effects on the final product, based in, essentially, two aspects: temperature control in the mold, both for heating and cooling processes and mold sensing. In this context, the project was divided into a set of activities in order to optimize each aspect independently and, at the end, bring together all the solutions.

At the end of the project, the following key points were reached, namely:

• The thin film capable of localized heating fulfilled the expectations in a laboratory environment. Furthermore, localized heating also allowed a decrease in injection pressures. However, the solution is not yet mature enough to respond the cycle time requirements found in the industry;

• The cooling system increased the efficiency of heat extraction allowing homogenization of the temperature;

• The application of sensors on the mold surface allowed to evaluate a set of parameters which are usually measured at points far from the zone of interest. This sensing methodology is non-intrusive avoiding the need to modify the mold to create specific channels for conventional sensing.

Project Reference

POCI-01-0247-FEDER-017620Funding

Intervention Region

North (63,09%) and Center (36,91%) of PortugalTotal Investment

1.222.723,45IPN Investment

169.631,09Total Eligible

1.220.713,32IPN Eligible

169.631,09EC Funding – Total

893.165,05EC Funding – IPN

127.223,32Duration

39 MonthsStart Date

2016-10-01End Date

2019-12-31Approval Date

2016-08-23Consortium

Moldit - Indústria de Moldes S.A.TEandM - Tecnologia, Engenharia E Materiais S.A.

Instituto Pedro Nunes

CENTIMFE - Centro Tecnológico da Indústria de Moldes, Ferramentas Especiais e Plásticos

Universidade do Minho

IPCA - Instituto Politécnico do Cávado e do Ave

Keywords

Injection Moulding;Smart Sensors;

Thin Films;

PVD Coatings.