StoneForm3D

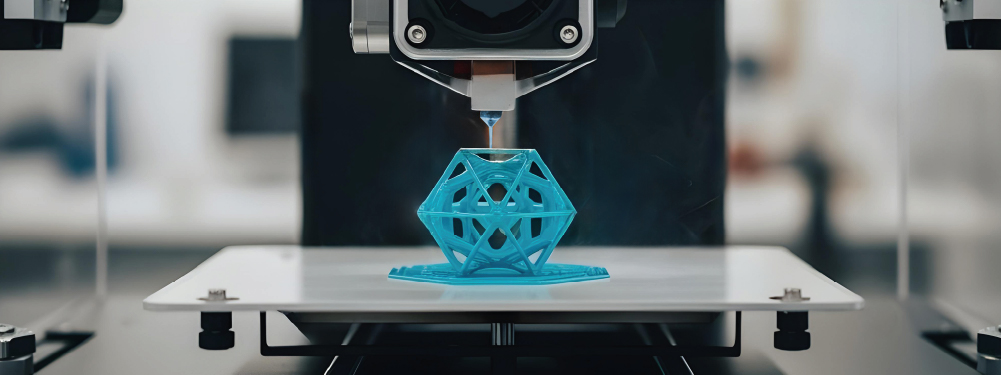

Direct digital fabrication of freeform architecture and design using by-products from stone processing

Challenge

The StoneForm3D project aims to develop not only a transformation and valorization process intended to recover residual slurries and powders from the natural stone extraction/processing sector, but also a highly distinctive additive manufacturing system for the on-site production of large-scale, custom-sized pieces that are impractical to transport.

Solution

The project implements a strategy based on the logic of a “short production and supply chain,” allowing the reintegration of a waste material (stone dust slurry) into the additive manufacturing of high value-added pieces, reducing landfill disposal and the consumption of natural resources. Currently, stone dust slurries are considered waste and, therefore, a problem to be addressed. The approach proposed in this project aims to reinterpret them as by-products with potential for valorization. It is believed that, if properly treated and valorized as “secondary” raw materials, they can be reintroduced into the innovative 3D printing process, integrating the concept of additive manufacturing that allows theoretically unlimited construction along one axis. The objects of study, in terms of project valorization, will include urban furniture and other products in the architecture and construction sectors, which can benefit from the on-site production of large-scale pieces, eliminating logistical and transport constraints. These systems enable mass production while allowing highly personalized designs, facilitating forms and creations that would otherwise be impossible to realize. The project inherently promotes environmental valorization through waste reuse, economic valorization through reintegration into the production chain, and positive consequences for the local region and economy.

Objectives, Activities and Results expected / achieved

1. Develop new compounds based on stone powder and assess their compatibility with binders and additives;

2. Characterize the stone paste and powder in terms of suitability for the selected additive manufacturing techniques;

3. Design, develop, and construct:

− A system for the utilization of stone dust slurries;

− An additive manufacturing production line equipped with a 3DP stone powder printer;

− An additive manufacturing production line with high-precision extrusion equipment;

4. Develop integrated computational tools oriented toward additive manufacturing;

5. Characterize the material obtained through the different additive manufacturing techniques;

6. Test and validate finishing processes on prototype ceramic pieces.

Project Reference

COMPETE2030-FEDER-02219700Funding

Intervention Region

PortugalTotal Investment

2.395.363,04IPN Investment

249.521,60Total Eligible

2.395.363,04IPN Eligible

249.521,60EC Funding – Total

1.826.290,64EC Funding – IPN

212.093,36Duration

36 MonthsStart Date

2025-07-01End Date

2028-06-30Approval Date

2025-04-11Consortium

MVC - Mármores de Alcobaça LdaInstituto Pedro Nunes

Universidade de Coimbra

Mármores Vigário Lda

AMCUBED Lda

M.Soares Gonçalves Lda

Cubo Solido Lda

SEAPOWER - Associação Para o Desenvolvimento da Economia do Mar

Keywords

Additive manufacturing;Stone dust slurry;

Waste valorization;

3D printing;

On-site production.