SmartLub

Smart self-lubricant coatings with controlled release of the lubricious agent for high temperature applications

Challenge

Self-lubricant coating systems with release of the lubricous species have enormous potential to be used in the protection of components working in extreme conditions of wear. However, the rapid release of the lubricious agent and, consequently, its total depletion from the coating hinders the transfer of these coatings to the industry. In the current project, solid lubricant coatings with long term lubrication properties are envisaged to be developed.

Solution

Main Objective:

To strengthen research, technological development and innovation.

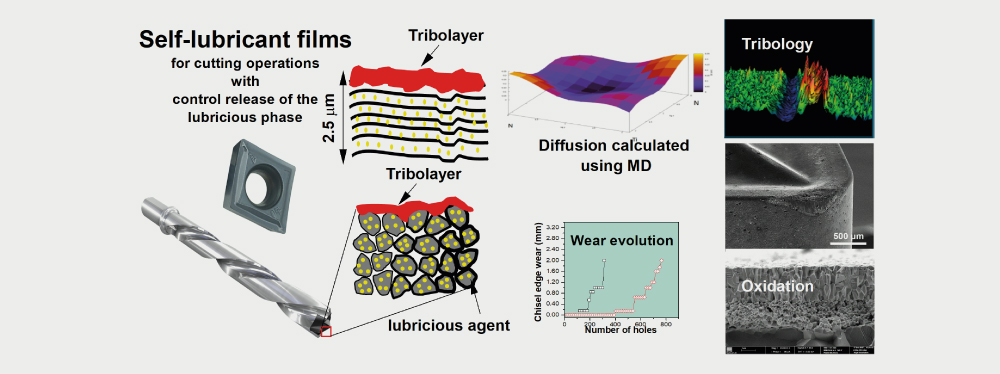

The main objective of SmartLub project is focused on the development of a new class of thin films with capacity to control the lubricious metal release, in order to get a controlled long-term solid lubrication. Nitrides and oxides, well known to have excellent chemical and thermal stability, will be sputtered with Ag (lubricious agent). By tailoring the structure of the different films and adequate dispersing of the lubricious specie in the matrix, fast depletion of the lubricious phase can be avoided.

Objectives, Activities and Results expected / achieved

Expected Results:

• Deposition of nitride and oxide coatings by HiPIMS;

• Atomistic simulation and model for Ag ions diffusion;

• Incorporation of Ag in nitride and oxide coatings;

• Silver surface segregation evaluation;

• Tribological characterization of the coatings;

• Potential industrial application.

Achieves Results:

Several coating systems without and with increasing additions of Ag, (Cr(Ag)O, TiSi(Ag)N, TiSiN/Ti(Ag), CrAl(Ag)N and TiAlSi(Ag)N)) have been deposited/optimized by sputtering and characterized for different properties. A simulation model to predict the diffusion of the lubricious element to the surface of the films was also developed.

Project Reference

POCI-01-0145-FEDER-031807Funding

Intervention Region

Center (100%) of PortugalTotal Investment

239.148,77IPN Investment

54.862,50Total Eligible

239.148,77IPN Eligible

54.862,50EC Funding – Total

FEDER - 203.276,45EC Funding – IPN

FEDER - 46.633,12National public financial support – Total

OE - 35.872,32National public financial support – IPN

OE - 8.229,38Duration

55 MonthsStart Date

2018-07-26End Date

2022-07-25Approval Date

2019-04-24Consortium

Universidade de CoimbraInstituto Pedro Nunes

Inovatools Portugal, Lda

Keywords

Self-lubricant coatings;Ag control release;

Kinetics of Ag diffusion;

Tribology.