LubEnergy

Engineering lubricious interfaces for enhancing energy efficiency

Challenge

The high economic growth of developed countries relies on the continuous and reliable access to affordable and clean energy. Diversification of energy sources has been pivotal to ensure energy security, while enhancing industrial output and competitiveness. Continued prosperity requires securing the sustainability of our energy use. A cornerstone in achieving this is the improvement of energy efficiency. In the case of manufacturing, as one example, improving the sustainability of machining processes relies on the elimination of hazardous waste, while increasing their energy efficiency through, for example, the efficient lubrication of tool/workpiece interfaces. In the case of transportation, as another example, the need to enhance engine efficiency is demonstrated by the fact that approximately 30% of the fuel used in vehicles is employed to overcome friction in the engine and transmission. Improved approaches for friction and wear management could not only result in enormous energy savings and benefits for industrial productivity, as weel lead to drastic reductions in greenhouse gas emissions.

Solution

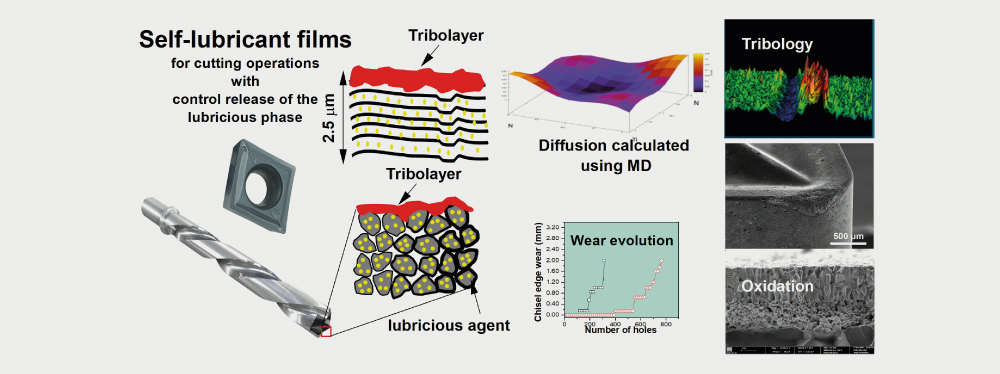

The solution is to extensively research the interactions of sliding bodies in the presence of a lubricant, in fundamental tribological systems. Among the materials that recently attracted significant attention in tribology, diamond-like carbon (DLC) films and ionic liquids (ILs) have, respectively, been evaluated as wear-resistant surface engineering solutions and friction-reducing lubricant additives (for engine oil formulations or machining fluids). Despite the relevance of the studies that highlighted the benefits of independently using DLCs to decrease wear or ILs to reduce friction, the combined use of DLC coatings and ILs in tribological systems is still unexplored. As DLCs films with different structure and composition can be obtained depending on the deposition technique and conditions and given the number of ILs available, identifying the origins of the interactions between ILs and DLCs surfaces under mechanical loading that lead to a reduction of friction and/or wear constitutes a critical step for establishing the knowledge necessary for rationally designing tribological systems that rely on the use of DLCs and ILs to achieve an improved tribological performance.

The main goal of the LubEnergy project is:

a) Evaluate the friction and wear response of a class of advanced coatings, namely alloyed DLC, lubricated with a class of green, energy-efficient lubricants, namely ionic liquids (ILs);

b) Develop an understanding of the interactions between doped-DLC and ILs controlling the lubrication performance.

Objectives, Activities and Results expected / achieved

Expected Objectives:

• To obtain knowledge needed to tailor sliding interfaces to reduce friction losses and increase components’ lifetime by decreasing mechanical wear;

• To achieve superior lubricating performance by combining an advanced class of wear-resistant coatings made of alloyed DLCs and a novel class of green lubricants (ionic liquids, ILs).

Expected Results:

• To perform an integrated study of material design, materials properties, and functional behaviour in doped thin films in the presence of new lubricant additive;

• To fundamentally understand the functional behaviour to reveal the importance of specific material properties, and subsequently use the emerging knowledge to dictate the needed structure and composition of DLCs and ILs.

Project Reference

UTAP-EXPL/NPN/0046/2021Funding

Intervention Region

Center (100%) of PortugalTotal Investment

49.998,94IPN Investment

49.998,94Total Eligible

49.998,94IPN Eligible

49.998,94EC Funding – Total

49.998,94EC Funding – IPN

49.998,94Duration

12 MonthsStart Date

2022-02-21End Date

2023-02-20Approval Date

2021-12-29Consortium

Instituto Pedro NunesPartners

University of Texas at AustinKeywords

Tribology;DLC;

Ionic Liquids;

Green Lubricants.