SMART ACTIVE MOULD (SAM)

Otimização do Desempenho Térmico da Moldação por Injeção

Desafio

A moldação por injeção é um processo de utilização consolidada na indústria por ser capaz de produzir componentes de qualidade superior, grande complexidade e liberdade de design, onde a replicação é rápida e eficaz. Contudo, o sistema de controlo de temperatura, apesar de ser um dos sistemas críticos do processo, é dimensionado de forma empírica. Como consequência, muitos defeitos em peças moldadas devem-se ao arrefecimento não uniforme da cavidade com as propriedades físicas e a aparência da peça moldada influenciadas pela sua taxa de variação.

Solução / Objetivo Principal

O principal objetivo do projeto SAM – Smart Active Mould – foi reforçar a investigação, o desenvolvimento tecnológico e a inovação.

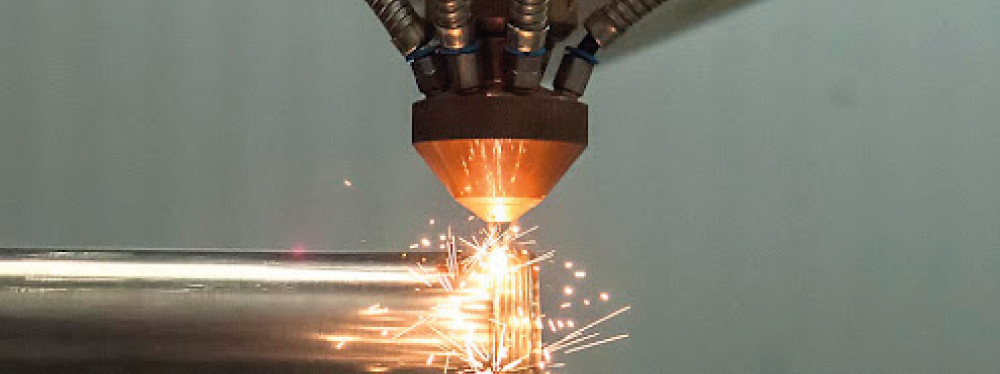

O projeto SAM teve como objetivo investigar uma solução inovadora ao nível do molde para controlar dinamicamente a temperatura do processo de moldação por injeção de peças poliméricas. A nova abordagem suporta-se em novas tecnologias de revestimentos finos e de fabrico aditivo, para proporcionar aumentos da qualidade da moldação sem defeitos ou distorções, reduções no tempo de fabrico das peças, possibilidade de processamento de novos materiais e produtos com especificações mais complexas e exigentes. A nova solução consubstanciou-se num salto tecnológico, já que foi pioneira na integração das diferentes tecnologias num único produto direcionado para a moldação por injeção de componentes poliméricos de elevada qualidade observados em produtos de gama alta.

Objetivos, Atividades e Resultados esperados / atingidos

O projecto SAM teve como finalidade atacar vários pontos considerados cruciais no processo de injecção com efeitos relevantes no produto final baseando-se em, essencialmente, duas vertentes: o controlo de temperatura no molde quer no processo de aquecimento quer no de arrefecimento e na sensorização do molde. Neste contexto, o projeto foi dividido num conjunto de atividades de modo a optimizar cada aspecto independentemente e, no final, aglutinar todas as soluções.

No término do projeto foram alcançados os seguintes pontos-chave de relevância, nomeadamente:

• O revestimetno fino, com a função de aquecimento localizado, cumpriu as expectativas em ambiente laboratorial. O aquecimento localizado ainda permitiu uma redução nas pressões de injeção. Contudo, a solução ainda não possui maturidade suficiente capaz de responder às exigências de tempo de ciclo encontradas na indústria;

• O sistema de arrefecimento aumentou a eficiencia de extração de calor aliando a uma homogeneização da temperatura;

• A aplicação de sensores na superfície do molde permitiu avaliar um conjunto de parâmetros que. normalmente, são medidos em pontos afastados da zona de interesse. Esta tipologia de sensorização é não intrusiva evitando a necessidade de modficar o molde para criação de canais especificos para sensorização convencional.

Referência do projeto

POCI-01-0247-FEDER-017620Financiamento

Região de Intervenção

Norte (63,09%) e Centro (36,9%)Investimento Total

1.222.723,45Investimento do IPN

169.631,09Elegível Total

1.220.713,32Elegível do IPN

169.631,09Apoio Financeiro da UE - Total

893.165,05Apoio Financeiro da UE – IPN

127.223,32Duração

39 MesesData de Início

2016-10-01Data de Fim

2019-12-31Data de Aprovação

2016-08-23Consórcio

Moldit - Indústria de Moldes S.A.TEandM - Tecnologia, Engenharia E Materiais S.A.

Instituto Pedro Nunes

CENTIMFE - Centro Tecnológico da Indústria de Moldes, Ferramentas Especiais e Plásticos

Universidade do Minho

IPCA - Instituto Politécnico do Cávado e do Ave

Palavras-chave

Moldação por injeção;Sensores inteligentes;

Filmes finos;

Revestimentos PVD.